Free information resources

articles, tutorials, tips and tricks

Adding new information daily

››› info

Servicing Brake Discs

| Installation If you need a new rotor, install it straight out of the box. Some of the lightweight rotors, made of a stamped steel hub with a cast-iron braking surface, could test as warped unless you check them with all lug nuts installed and tightened. Note: There are some rotors that are a real bear to remove, so if the vehicle manufacturer indicates special tools or if a press is necessary, a rotor can be machined on the vehicle. You're best off leaving this to a properly equipped pro. Both Sides, Please Clean lug nuts and stud threads with a mild solvent and wipe dry. Don't lubricate them, as today's torque specifications are based on clean, dry threads. One of the most important tools you can use is a torque wrench. When you're re-indexing a rotor, be sure to reinstall the lug nuts and torque them to specifications in at least three stages. Use a crisscross pattern for each stage until all are tight. |

A typical vented disc brake assembly. The hole in the caliper is for inspecting the pads. |

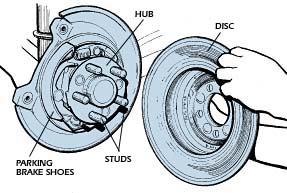

The brake rotor, the disc in disc brakes, mounts on the hub with the wheel, and both rotor and hub are held by the same studs and lug nuts. When you apply the brakes, the hydraulic device called the caliper clamps the brake shoes (also called pads) against the rotor, and the friction material on the shoes stops the spinning of the rotor (and therefore the wheel). The friction material on the shoes causes the energy of wheel and rotor motion to be converted to heat, and the rotor temperature can soar to more than 1000° F in a hard stop. That heat has to be dissipated very quickly so that the rotor can cool down for the next stop. Because front brakes do about 75 percent of the work in a front-drive car (over 50 percent in a rear-drive), the front rotors have to be able to dissipate a lot more heat than the rear brakes, drum or disc. As a result, the front rotors on virtually all cars today have two contact layers separated by a vent area, which resembles a paddle fan, to throw out hot air. This design not only gives each brake shoe a separate disc, but the airflow through the center provides greater cooling. Some high-performance cars also have vented rear discs.

|

|

Removing disc-type rear brakes may require backing off the parking brake adjusters first to relieve the tension of the parking brake shoes |